Many people think about replacing or laying new flooring during the next repair or when finishing new housing. The modern building materials market offers various types of coatings, and one of the most popular today is the floorboard.

What are the advantages of this material? Wood flooring is a great alternative to traditional wood flooring. It has all its qualities, thanks to which you will become the owner of a warm, pleasant to the touch, eco-friendly, visually attractive floor. The floorboard was created as a replacement for parquet flooring and solid wood. Today in Europe, more than half of wooden floors are made from this material.

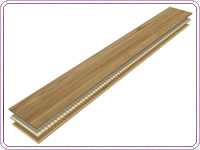

The structure of the floorboard

Unlike parquet, parquet board consists of three layers of different types of wood glued together. The top layer of the board with a thickness of several millimeters, which can be different in different models and ranges from 1 to 6 mm, is made of valuable wood with a beautiful texture. The middle and lower layers are made of less expensive wood, most often used for this pine, larch. In the upper layer of the fiber are arranged parallel to the length of the board, on average - across, and in the bottom - again in parallel. As a result of such a multi-directional arrangement of the fibers, the parquet board acquires such a positive quality as the minimum deformation of the floor after installation.

Types of floorboards

Different types of floorboard differ in size, types of wood used in the upper layer, the number of lamellas, that is, slats in one board and the top surface. When choosing a material you need to consider all these indicators.

For the top layer of the board, traditional or exotic wood can be used. Most often, you can find a board made of oak, beech, ash, walnut, birch, cherry. Exotic breeds include merbau, jatoba, wenge, tali, dussia and other breeds. Different types of wood has its own characteristics, and are distinguished by hardness, pattern, color. The color of the floorboard can be chosen to your taste from almost white to black. Modern processing methods give the tree a variety of colors and shades. When stripping wood becomes more juicy color, bleaching gives it a whitish tint. The application of the treatment of the type "antique" artificially age the tree, gives it a noble shade, and by combing the soft wood fibers get a relief, ribbed surface.

Even in the factory floorboard is coated on top with varnish or oil. Acrylic varnishes are most commonly used, which are applied in several layers, creating a smooth, durable surface with high wear resistance. The coating consisting of a mixture of oil, wax and natural resins is less durable, it is more susceptible to mechanical damage, but the wood texture of the floorboard covered with oil looks brighter, clearer and more saturated. There are lacquer coatings used by Tarkett, which looks like oil, but has the properties of varnish.

Floorboard manufacturers

The choice of floorboard to a large extent depends on the manufacturer. The leaders in the production of this flooring are the companies Kahrs, Tarkett (brands Tarkett and Sinteros), Upofloor (brand Karelia), Barlinek, Haro Parquet, Weitzer Parkett, Amber Wood.

The Swedish company Kahrs produces very high quality floorboard. The company has received many international certificates confirming the quality and environmental safety of its products. Behind the company there is a huge experience in the production of floorboard - after all, it was the founder of Kahrs who invented this flooring in 1941.

UpoFloor together with Karelia form the global corporation Karelia-Upoflor.

The Karelia brand has been a leader in the market for wood flooring materials for several decades. The floorboard of this company from Finland has long been popular with buyers. The quality of the company's products is carefully monitored by electronics. Karelia floorboard is not cheap, it is made from hardwood with high hardness and has high wear resistance and durability. A floor with such a board is the best solution for a private house.

The UpoFloor board is made mainly from traditional wood species: oak, beech, walnut, maple and cherry. The floorboard of this company is represented by groups "Select", made of core wood with a calm pattern, "Natur" - with a lively pattern of wood fibers, "Roustik" - which uses natural variability of wood and "Country" with an exquisite pattern for a lot of knots .

Barlinek floorboard is produced by a Polish company and combines high quality, excellent aesthetic properties, ease of installation and restoration. Since 2007, the company launched production in Vinnitsa in Ukraine. The company Barlinek offers the floorboard of the Exclusive groups with natural monochromatic shades of lamellas, Select - with a small number of small knots and zabelin and Family - boards with different shades, an arbitrary wood pattern, with zabelins and knots. The company's products are the best combination of quality and price.

Tarkett company was originally established as a furniture factory, but over the years of its existence, it has gradually transformed into the largest enterprise, the main direction of which is the production of flooring, including floorboard. Parquet board is produced in Serbia, and in general the company has several large factories in Russia and Ukraine. Currently, the Tarkett brand is popular not only in Europe, but throughout the world. Tarkett floorboard is made from hardwood. The company Tarkett introduced and mastered the technology of production of parquet boards in a modern form using three layers of wood, the use of seven-layer protective lacquer coating and proposed new types of the strongest combination of Combilock and Ultralock boards. Tarkett floorboard - high quality guaranteed and beautiful, reliable and durable floor.

Possible sizes and prices

The floorboard can differ in thickness and strength of the upper working layer, the size of individual boards. The total thickness of the board can be from 8.5 to 25 mm, and the thickness of the working layer - from 0.6 to 6 mm. When choosing a parquet board, one should take into account that the thicker the working layer is, the easier it is to restore the floor by polishing, which is crucial for its durability. The length of the board depends on the manufacturer, the length can vary from 1,800 to 2,500 mm and the width within 130-200 mm.

The cost of floorboard depends on the popularity of the manufacturer, the value and thickness of the wood of the working layer and can be from $ 20-60 to $ 95-110 per square meter. More expensive is the flooring of exotic woods: merbau, yatoba, wenge and others.Single-sided parquet board with a solid layer of veneer is 1, 5-2 times more expensive than three-strip, recruited from small lamellae.

Laying floorboard

Unlike parquet flooring, which only a professional can handle with high-quality installation, laying of floorboard is simple and accessible to any home craftsman. Laying can be carried out in a floating way, gluing boards to the base and placing on the logs. Before work it is necessary to level the surface, the room should not be hot, not cold and not too humid.

Work on laying floorboard costs $ 8-10 per square meter, so you can save money when doing it yourself. Stacking can be done using the instructions that come with the board. You can use the floor immediately after installation, no additional work is required.

Operating rules

In winter, the houses with central heating are too dry, which has a bad effect not only on health, but also on the condition of the wooden floor. To increase the humidity, you can use special humidifiers, place indoor plants in the room.

Over time, the surface of the floorboard may appear traces of mechanical damage, scratches. In this case, the floor can be restored using sanding the working surface, after which varnish is applied on top of several layers. After such a restoration, the floor of the floorboard again looks like new.