Depending on the scope of use of PVC coatings, which include linoleum, divided into semi-commercial, commercial and domestic. Commercial coatings also include special linoleum.

Household linoleum. Used in residential areas. It has a luxurious range of design and colors. Basically, these are heterogeneous coatings with a protective layer of 0.15-0.3 millimeters.

Commercial linoleum. It is heterogeneous and homogeneous. Heterogeneous commercial linoleums have a more durable protective layer than household ones. Also, the protective layer is thicker here (up to 0.8 millimeters) and quite often contains various additives - insulators, antistatic agents and even corundum. Such wear-resistant coatings are used in premises with a large load: in industrial premises, large stores and offices.

Semi-commercial linoleum. According to its characteristics is located between the commercial and domestic. Designed for hospital wards, hotel rooms, small offices, will serve well in the kitchen and in the hallway in the apartment.

Special linoleum and industrial linoleum also belong to the category of commercial. Such coatings have special specific properties: very high electrical, hydro and sound insulation, cold or heat resistance, resistance to aggressive media, etc.

Household linoleum

It has a thickness of from 1.5 to 3 millimeters, with a wear layer of 0.15-0.35 millimeters (it may not be). Rolls are available in a width of 1.5-4 meters.

.jpg)

Photo: technostroy-m.ru

Such linoleum has the following technical characteristics:

- Weight: 1.25-2.25 kg / m2

- Price: 2.5-10 euros per 1 m2

- Flexibility: when grasping a rod of 45 mm diameter there should be no cracks

- Water absorption: not more than 1-1.5 percent

- Heat conductivity: 0,018-0,035 W / m * K

- Sound absorption: 13-18 dB

- Residual deformation: not more than 0.2 mm

In domestic linoleum inside, a thin sheet of fiberglass is placed on the foam base, which serves as a reinforcing function - it does not allow tearing and stretching. Foam PVC is applied to the fiberglass from below and above. On the reverse side, linoleum looks like a sponge with small pores. From above roll the drawing which is filled in with a thin layer of colorless PVC. This protection is over time. To increase the service life of the coating, many manufacturers in the factory conduct additional processing of its surface with different compositions, thereby increasing the wear resistance and facilitating the care of it.

The wear resistance of this type of linoleum depends on the thickness of the protective PVC top layer. One of the most expensive components is pure PVC. So the thicker, the greater the price. To allow customers to save money, manufacturers recommend laying in bedrooms and living rooms linoleum with a protective layer of 0.15 mm, in children's rooms and dining rooms - 0.2 mm, in kitchens, hallways, corridors - 0.25 mm, in office rooms with high traffic intensity - 0.5 mm, with average - 0.3 mm. It should be noted that these figures indicate the thickness of the protective top layer of linoleum. In stores, you can find out information about the thickness of this layer from sales assistants, but only in those cases when you chose a product from a well-known company. Products from the party "without a clan and tribe" hardly comes with such information ...

However, the most important reason for acquiring linoleum from well-known companies is the safety of health. In the process of making vinyl linoleum, plasticizers are used to keep the coatings flexible. But in large quantities they have an adverse effect on health. In appearance it is impossible to determine the amount of plasticizers.The protective layer of high-quality linoleum contains the minimum amount of plasticizers, which is why it cracks when bent in the cold. However, when cracks appear on the substrate (inside out), this also indicates a poor-quality product. In good linoleum, when bending, the substrate does not crack, it does not break when stretched, and there is a minimum of plasticizers in it.

Semi-commercial linoleum

More durable than household, but in terms of characteristics inferior to commercial. Available in rolls, the width of which can be from 2 to 4 meters.

The linoleum of this type is guaranteed from 7 to 20 years depending on the manufacturer. It is used in residential and public places and office premises with low traffic.

.jpg)

Main characteristics:

- Protective layer: 0.5-0.6 mm

- Price: 5.5-15 euros per 1 m2

- Residual deformation: not more than 0.10 mm

- Weight: 1.6-2 kg / m2

- Sound absorption: 12-16 dB

- Flexibility: when grasping a rod with a diameter of 10-40 mm crack should not be

Use of semi-commercial linoleum

Laying semi-commercial linoleum can be performed both in small offices and in apartments. A wide range of colors allows you to choose this type of linoleum for almost any interior. Such linoleum is similar to household linoleum, it is quite simple to fit and unpretentious to care, but it differs in improved protection from mechanical damage and more wear-resistant.

Semi-commercial linoleum is perfect for the kitchen and corridor to the apartment, where more than three people live, there are small children and pets. The load on the floor in the hallway and the kitchen at the same time no less than in the office.

The main raw material that is used in the production process of semi-commercial linoleum is the composition of PVC. This coating is made in several layers: the main part (substrate), the fiberglass part, the layer with a pattern or pattern, a protective top layer. Thanks to the top layer, this type of linoleum gets additional wear-resistant properties.

The cost of semi-commercial linoleum is less than commercial counterparts, but it is slightly more expensive than household linoleum. The final price depends on the thickness of the polymer layer, the hardness of the substrate, the name of the manufacturer. A variety of different colors of this linoleum allows you to use it in residential apartments and houses.

Manufacturers of semi-commercial linoleum

- Tarkett (Sweden-Russia)

Popular collections:

- Tarkett Force. It is one of the most expensive collections of semi-commercial coatings Tarkett, as well as the largest (38 colors) and durable. Produced in the town of Backa in Serbia and delivered to the warehouse of the Russian plant Tarkett, located in the town of Otradny in the Samara region. The Force collection is produced under the Tarkett brand, it is covered with a protective 0.6 mm layer of polyurethane.

- Tarkett (Sinteros) Sprint. It is the cheapest semi-commercial linoleum Tarkett, which is produced under the brand Sinteros. Linoleum has a protective layer with a thickness of 0.4 mm, that is, the thinnest possible in the semi-commercial group of these coatings. A small range of colors, 7 common designs - 3 patterns “crumbs”, cork and 3 parquet patterns, perfectly corresponding to the colors that are more often chosen for budget objects.

- Tarkett Moda. Heterogeneous semi-commercial linoleum, having a protective layer of 0.5 mm, which is 0.1 mm more than the Sprint. The collection is produced under the brand Tarkett. It is more durable and popular flooring than Sprint. There are no patterns for floor rolls in the collection that need to be combined in the process of laying. The collection includes seven "chips" saturated colors.

- Tarkett Idylle Nova. It has a 0.5 mm protective layer. This is the largest (35 designs) and a beautiful collection of linoleum of this group with a base, which consists of a heat and sound insulation layer (TZI) and foamed polyvinyl chloride (PVC). Due to this composition, the collection is considered durable, warm and beautiful home flooring.

- Armstrong (England)

- IVC (Belgium)

- Juteks (Slovenia) and others.

Commercial linoleum

This coating is characterized by increased wear resistance. This type of linoleum is stained throughout the thickness, it has a thicker protective layer. It is mainly used in public buildings with a large flow of people, where flooring is necessary with the highest degree of durability. Of course, it can be used in residential buildings, but because of the high cost (10-40 euros per 1 m2), its use in residential premises is very limited, where you can be content with inexpensive and less wear-resistant linoleum.

.jpg)

Photo: linoleum-stroi.ru

Commercial linoleum has the following characteristics:

- Weight: 2.8 kg / m2

- Price: 10-40 euros

- Residual deformation: not more than 0.02-0.10 mm

- Protective layer: up to 0.8 mm

- Sound absorption: 6-10 dB

- Flexibility: there should be no cracks when grasping a rod with a diameter of 10-40 mm

The service life of this coating: 10-25 years.

Depending on the manufacturing technology and composition of the PVC fabric, commercial linoleum is heterogeneous and homogeneous.

The following companies are engaged in the production of commercial linoleum: “LG Hausys floors” (South Korea), “Juteks” (Slovenia-Russia), “IVC” (Belgium), “Armstrong” (England), “Forbo”, “Tarkett”, etc.

Use of commercial linoleum

Used in public places with high traffic (business and shopping centers, shops, educational institutions, offices, cinemas, etc.). This coating has increased wear resistance, fire safety in accordance with international standards ISO 9001 and ISO 14001, resistance to detergents and other aggressive agents.

Special coatings

The group of commercial linoleum also includes special coatings with improved certain characteristics.

For example, subspecies are different - anti-slip (intended for wet rooms), acoustic (with high sound absorption qualities up to 19 dB and noise insulation), antistatic (ensures no static voltage, the coating accumulates a charge of no more than 2 kV), etc.

Industrial Linoleum

Commercial name commercial linoleum which can be used in warehouses, in production rooms, shops is called. It withstands very large loads - it is not squeezed under a weight of up to 20 tons, it is moisture-resistant, non-flammable, resistant to chemical influences. This is a very special type of flooring for places where vehicles travel, and where conventional commercial linoleum will not stand - even homogeneous.

Photo: spkompani.ru

Manufacturers of industrial linoleum

Armstrong company (USA) - releases the Linodur LPX collection. It is a natural current dispersing linoleum with a width of 2 m. It lies well under the loaders and has been serving for 5-10 years. In addition, it is subject to recovery in case of damage.

In Russia, industrial linoleum is produced in the Moscow region by the company GK AVTO. Their products are also used in public transport and other places.

Homogeneous linoleum

Consists of PVC layer that is uniform throughout the thickness. As a rule, homogeneous coatings have a thickness of from 1.5 to 3 mm. On such coatings the pattern is quite simple: granular, monophonic, under "marble", etc. It is used in rooms with high operational loads: front doors, airports, shops, corridors, etc.

Due to the fact that polyvinyl chloride in its pure form is quite expensive, talc, kaolin or limestone are added to the linoleum mass. Basically, the cost of linoleum with a high content of filler is less, while coatings have a higher specific weight than high-quality coating.

Heterogeneous linoleum

Heterogeneous coatings have a thickness of 2-6 mm and consist of several layers. In their production is used reinforcing fiberglass with a width of 1.5-4 meters, acting as a kind of "skeleton" for the canvas. After that, the base layer of PVC is rolled onto the impregnated layer. Then a drawing is applied on it (depending on the design), protected by a transparent film - from pure PVC or polyurethane.In addition to plastic granules, stone chips and metal dust are also added to this layer, due to which a more unusual coating design is obtained. The wear resistance of the coating largely depends on the thickness and strength of such a film (0.15-0.8 mm).

Such linoleum is more difficult to manufacture and more expensive than homogeneous. However, it has a chic selection of drawings.

Heterogeneous PVC coating has the following structure:

.jpg)

1. protective layer;

2. drawing design;

3. foam PVC sheet;

4. fiberglass;

5. substrate

Substrates of modern PVC linoleum are made of various materials: synthetic or natural fabrics, foam polymers, felt and cork oak bark. However, often the base is made of foamed polymers.

What is better - heterogeneous or homogeneous linoleum?

With homogeneous linoleum there can be only one problem - it is lime. When you add a large amount of lime, when used, it begins to appear on the surfaces with whitened wiped paths. It absorbs dirt and cannot be removed with detergent; sanding the floor with a polishing machine will be necessary. From this can save polyurethane protection, applied in the factory to the surface. It protects the coating from black marks left by the shoe. Mastic is also used as a protection, but a new layer will have to be applied every three to six months, grinding off the old layer again.

To determine the amount of lime you need to bend the linoleum. The appearance in the places of the fold of white stripes means that the lime in the material is more than the norm. In cases where linoleum is torn at the bend, it means that lime is a very large amount.

In comparison with the homogeneous heterogeneous linoleum is more unpretentious in the care. It does not need periodic rubbing, wet cleaning will be enough.

Linoleum Classes

There is a European standard EN685, given that flooring manufacturers assign each type of flooring a particular class corresponding to a certain intensity of use.

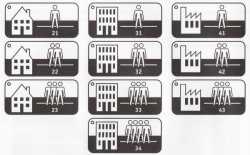

Simple logic: there are three main types of premises: industrial, office and residential. Each of them corresponds to a specific figure and icon: plant (4), office building (3) or a house (2).

.jpg)

In each of these types of premises, the intensity of influence on linoleum is also different: very high, high, medium or low. The intensity of the impact is indicated by humans: 1, 2, 3 or 4 - the more of them, the more intense the load can withstand the coating.

Depending on the strength characteristics, method of manufacture, thickness of the wear layer, one of the classes is assigned to the linoleum:

1. For residential premises (corridor, kitchen, living room, study, nursery, bedroom, where 1-2 people live, etc.) - household linoleum. To sphere of use 21st grade includes a bedroom, a storage room and a wardrobe, 22nd - dining room, study, living room, 23rd - corridor, hallway and kitchen.

2. Living rooms (corridor, living room in an apartment where three or more people live, children's room with active kids), small offices - semi-commercial linoleum (23-31 class).

3. Office premises with medium and low traffic (meeting rooms, small offices, hotel rooms, small offices, etc.) - semi-commercial linoleum (31-32 class).

4. Office and office space: commercial linoleum. Short-term intensity of use - 31st grade - hotel rooms, meeting room, conference room. Medium degree of application - 32nd grade - boutique, office about 20 people, reception. High intensity - 33rd grade - educational institutions, a large office. Very high intensity - 34th grade - retail outlet, game room, airport and train station waiting room.

5. Production facilities: industrial linoleum. 41st grade used where they work sitting and rarely use vehicles.These are premises in factories for the repair and production of precision electronics and mechanics. 42nd grade the intensity of the use of warehouses and others, where they work standing and use transport mechanisms. 43rd grade (high intensity) - used in large warehouses and production workshops.