Versatility and variety of textures, modern technologies and outstanding technical characteristics, reasonable prices and excellent quality - all this is laminate flooring! Laminate flooring is a multi-layer artificial floor covering with a base made of fiberboard and an upper decorative wear-resistant layer. How to choose a quality laminate that is ideal for your home or apartment? We will understand the facts.

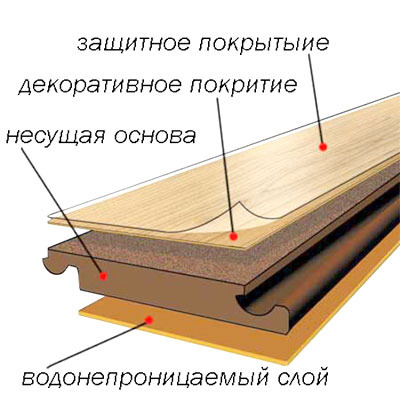

Fact No. 1. Laminate flooring consists of four layers.

- Stabilizing bottom layer - protects against deformation.

- Bearing layer - plays the role of insulation and insulation from noise, protects against moisture, locks crash into it.

- Decorative layer - paper with a pattern imitating woody structures.

- The top layer - protects the coating from abrasion and mechanical loads.

Fact No. 2. Currently, only four operational classes of laminated coating are being produced.

Photo: laminatplus.ru

Operational class 31 - used in commercial premises with minor loads, serves up to three years. In the living room (pantry, bedroom) can serve up to twelve years.

Operating class 32 - used in commercial premises, able to withstand medium loads, serves up to five years. In a residential environment (corridor, kitchen) will last up to fifteen years.

Operational class 33 - used in commercial premises, can withstand intense loads, will last up to six years. In terms of residential premises, regardless of the place of laying serves up to twenty years.

Operational class 34 - used in commercial premises with ultra-intensive loads (stations, airports, dance clubs), will last up to fifteen years. In a residential environment can serve for about thirty years.

Fact number 3. There are five classes of wear resistance of laminate flooring.

Wear resistance of the product is determined by Taber-test. It consists in the impact on the surface with an abrasive wheel with the change of abrasive paper through a certain number of turns. The test is carried out until the top layer begins to wear out.

The number of revolutions, depending on the quality of the product, varies between 900 and 20,000, based on the specific wear resistance characteristics demonstrated during the test, the product is assigned the appropriate class. Each class corresponds to a certain number of turns, which the coating withstood, in total there are 5 classes of wear resistance:

- AC1

- AC2

- AC3

- AC4

- AC5

The test is carried out in accordance with European norms EN 13329, in force since 2000. According to them, there is a change of abrasive paper through two hundred turns of the circle. Previously adhered to the standard EN 438, in accordance with which the paper was replaced after five hundred turns. In this regard, manufacturers can indicate on the packaging data for both classification standards.

Fact number 4. The top layer of the laminate is not necessarily smooth.

The top layer of the laminate can be:

- Smooth - the layer has a smooth, sometimes glossy surface. This makes the coating slippery, it leaves footprints

- Matte - natural appearance, non-slippery coating, footprints are hardly visible

- The texture is the most modernized coating, dotted with irregularities, creating a brushing effect. The maximum natural appearance imitating a parquet or massive board

- Chamfers - roundings and bevels along the edges of the board, give the coating maximum natural appearance, indistinguishable from solid wood.When water penetrates the coating structure, its swelling will not appear as clearly as in other cases.

Fact number 5. The most common five sizes of laminate

In practice, five sizes of coverage are in demand:

- Thickness - 7 millimeters

- Thickness - 8 millimeters

- Thickness - 9 millimeters

- Thickness - 10 millimeters

- Thickness - 12 millimeters.

The thickness of the product, in most cases, is directly proportional to its value. This is due to the fact that in a thicker coating locks are much stronger, which means that the product is less exposed to external loads and can be laid on an unaligned base.

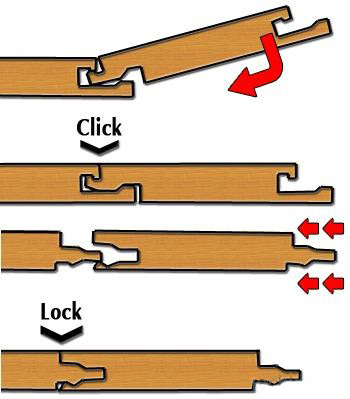

Fact No. 6. There are two groups of locks for laminated coating.

There are two types of locks LOCK and CLICK.

LOCK locks are considered the most economical option, they are made using the milling technique. From one side of the panel it makes a spike, and on the opposite side a groove with a fixing comb, in the process of laying, they are joined, providing a reliable and durable fastening. The disadvantage of this locking connection is the constantly occurring friction between the groove and the spike, which over time leads to abrasion of the locking comb and contributes to the deterioration of the contact of the locking elements. As a result, cracks are formed at the junction that are not subject to liquidation.

CLICK locking systems, involves fixing and locking the panels at a 45 degree angle. In this case, the locks cannot be damaged during assembly, and during operation they are not subject to friction, even with increased mechanical loads. This is due to the fact that the connected panels are constantly under voltage, which contributes to their reliable connection. Also, the laminated coating with this locking system can repeatedly be disassembled and assembled, the most popular brands guarantee up to four assembly and disassembling cycles.

Fact number 7. There is a fundamental difference between moisture resistant and waterproof laminate.

Distinguish moisture resistant and waterproof coating, both of these types differ radically - as they are made of different materials.

The moisture-resistant laminated coating in its structure has a HDF-plate, treated with a water repellent of green color, which is clearly visible. When buying, pay attention - the density of the panel should be at least 900 kg / cubic meter. (this can be found in the product specification).

The waterproof laminated coating is on average twice as expensive as moisture resistant. The basis of such a laminate is not HDF plate, but plastic. Water to this floor is really not scary. "PVC-based laminate and plastic composite are not afraid of moisture in general, and joint seals do allow for a good laid laminate to survive real floods." - says Evgeny Shamenkov, Financial Director of Aqua-Step LLC in an interview with the magazine "MyHome".

Fact No. 8. Laminate has several advantages.

The high-quality laminated parquet has obvious advantages; in total, we can highlight the TOP-6 of the best properties of this material:

- Resistance to external effects - pressure, loads, abrasion. There are no traces of heavy items, which allows you to freely move furniture.

- It withstands high temperatures and is fire resistant.

- It does not need careful care - no polishing or cycling is needed, it is enough to wipe with a damp cloth.

- Environmentally friendly material - does not cause allergies, prevents the spread of bacteria and the accumulation of dirt, does not emit harmful substances into the atmosphere.

- Simplicity of installation - easily laid on most types of coatings, for example, PVC floors, seamless, wood, heated floors or covered with linoleum.

- This durable coating - its service life depending on the class in residential conditions varies from 10 - 30 years, some manufacturers give a lifetime warranty on their products.

Fact number 9.The laminated flooring has drawbacks that appear during operation.

Despite clear advantages, this is not an ideal floor covering.

The disadvantages of laminate:

- The coating does not make laying on a wet and fragile surface, the drops should not exceed three millimeters over an area of 1 m2.

- Fear of moisture - not all types of products are able to withstand moisture, in most cases when water gets between the panels they crack and crumble.

- Swelling of the coating - if the laying technology is disturbed - bubbles may appear and the coating will swell.

- Squeak - if the product was laid in violation of technology, in particular, surface irregularities exceeded three millimeters per square meter.

- Despite the fact that the cost of this coating is one of the most democratic, the price of quality materials is quite high.

Fact number 10. There are three ways of laying laminate flooring.

In practice, laminated flooring is laid in three ways: direct installation; diagonal styling; curly styling.

Direct laying is carried out parallel to the walls. Trimming costs range from 4 to 7%. It runs along or across the line of light, in the first case the light falling from the windows prevents the shadow from being cast by seams between the panels, which creates a visually perfectly smooth surface. The second option involves laying perpendicular, relatively long walls, which allows you to expand the room visually.

Diagonal styling involves cutting costs up to 15%; this is the least economical way. However, this contributes to the maximum increase in visual space, this method is the most expensive and difficult to perform.

Photo: onlinesrv.ru

Figured styling is possible only when using a special locking system. Laying involves the creation of a full or incomplete square, single Christmas tree or English dressing, while due to the beveled panel edges, it is possible to perfectly imitate the texture of natural parquet.

Photo: pol-master.com

Finally

When choosing a laminated coating, you need to focus on operating conditions. It makes no sense to overpay for coverage with wear resistance class 34 for laying in the bedroom, just as it is absolutely unprofitable to equip a dance floor with a coating with class 31.

Choose laminate from well-known manufacturers - they comply with the production technology, their products are environmentally friendly and reliable. Ask before you buy reviews on the products of the selected brand.

Choose carefully and you will be able to purchase laminated parquet at the best price and ensure its long service in your home.