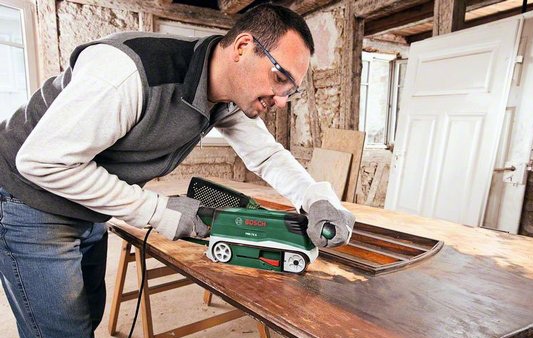

Belt sander it is customary to call special equipment that is intended for grinding surfaces, cleaning, fitting, marking, shaping, leveling and polishing, and even grinding. Uncomplicated sanding machine similar to the design of electroplane. Its working element is a grinding tape, which is glued into a ring, which is put on the rollers connected to the motor drive. These devices are classified according to the width of the tape, the number of speeds and energy consumed, the field of application and other indicators.

It is likely that many have already used the belt grinder before, and can not boast of positive experience. To work with the device was not a burden, you need to follow a few rules and understand the intricacies of using this equipment. To enjoy the work of the grinder, you must be able to choose the right instruments and accessories. You need to know, for example, which tapes are best used for working with these or other materials, and how much power a machine should have to achieve the desired result, etc.

Scope of belt grinders

Among the variety of grinding technology, being the most popular, tape machines are designed for rough processing of wood and other materials. With their help, carry out:

- fitting cut lines;

- precise trimming;

- leveling and also pre-grinding rough surfaces;

- the formation of parts;

- sharpening;

- removal of layers of wood, plastic, glass or metal.

Making rough surface treatment, tape machines, due to their power and speed of rotation of the working surface, are able to quickly remove wood layers of various thickness. To do this, the rollers must wear a coarse tape of the width that corresponds to the parameters of the grinder. This equipment copes with clearing the surface after processing with a plane, they can align the butt parts of the blanks and their ends. Grinders can expand the doorframes, without fear of accidentally cutting off excess, they perfectly cope with cutting grooves, etc.

With tape machines, you can quickly and efficiently level up the filler surfaces and scrape off the old paint. If you need to sand the window frame, door or battery to the base, then you will not find a better device for this purpose. Due to the technical characteristics, which are very diverse, these devices are used for peeling paint from large areas of car bodies during car repairs. The robust housing allows the device to be fixed on a table or stand for processing small workpieces with manual feed.

The choice of grinding machine

Choose a grinding machine necessary depending on the type of work to be done. For example, for processing large areas, it is more expedient to use devices with a wide belt, and for processing a narrower surface, it is better to use a device with a narrow sanding belt.

Specifications, consumables

Knowledge of the technical characteristics of these simple devices will facilitate their selection and help to better carry out the planned work. Usually belt grinder choosebased on technical specifications such as:

- Power;

- Tape length;

- Tape width;

- Belt speed;

- Possibility of adjustment of turns;

- The presence of a smooth start;

- Weight;

- Manufacturer.

Power machines varies from 350 to 1200 watts, and you will need to choose a device, depending on your needs.Another parameter affecting the quality of work is the belt rotation, which is carried out with a linear speed of movement of 75 - 500 m / min. Some models have the function of changing speeds, thanks to which you can perform work better. A smooth start of the electric drive when the device is turned on will also help you improve the quality of work. But there are a large number of models, low cost, in which there are no such additional functions, but the quality of polishing remains at a height.

Important element belt sander is an sanding beltwithout which the device will not be able to perform its functions. It should be noted that one of the defining characteristics are the shape, width, length, grain of the material from which the abrasive is made and the tape itself. From the combination of all the characteristics depends not only the quality of work, but also the life of this accessory. In the grinders use a looped tape, which is based on cotton, nylon, cloth, polyester, polyester, paper, fiber or other materials.

The abrasive can be made of aluminum dioxide (electrocorundum), silicon carbide or zirconium oxide. To date, the standard width varies from 30 to 140 mm. The most common - 76 mm. The length of the tape can be 457 mm, 533, 610 or 620 mm.

An important characteristic is the size of the abrasive particles. For the initial rough treatment, a tape with a grain of 40 or 60 is used, alignment will require an abrasive with values of 80 or 100, and for finer processing a material is used whose grain is in the range from 120 to 320. All ribbons are color-coded by their parameters.

All devices are equipped with a special device - a dust collector, into which dust enters into the bag with the help of a fan. You can connect a vacuum cleaner to any model, which is able to provide better dust suction, but some models in the kit come with special nozzles.

The finer points of the grinder, tuning and efficiency

Before proceeding with the processing of wood, you need to familiarize yourself with some subtleties that will help you work with the tool. If it is necessary to perform rough processing, then it is best to grind at a slight angle to the wood fibers, this will ensure quick cutting of the layer of the required thickness. In order to make the surface smooth, it is necessary to guide the tool along wood fibers. Virtually all models are designed, with the center of gravity shifted closer to the bottom, so you do not need to press the machine during operation if you do not want to make a notch or groove. Work is recommended to perform smooth, unhurried circular movements, without immersing the device deep into the wood. Do not dramatically change the speed, pull the tool and change the direction of grinding. In order to protect the power cord from falling under the work surface, flip it over your shoulder.

Often when performing grinding work, horseshoe-shaped grooves occur. This is usually due to the touch of the edge of the working surface. To solve this problem, it is recommended to use new or, in extreme cases, peeled tapes. Abrasive grit should not be more than 120. It should be borne in mind that in rare cases, the workpiece can be left without scratches and grooves along the edges. Therefore, grinding work must be carried out before cutting the element to the final size.

Grinders that have the function of a smooth change of speeds, allow you to work at maximum speed, and you can slow it down in delicate places without stopping work, without turning off the tool.

Despite the simple device, the grinder still requires a small settings. For example, you should always ensure that the directional tape is installed correctly. You can learn about the direction of the arrow, which is drawn on the back side.Any tape, directed or not, must be centered relative to the rollers. To do this, turn the machine upside down and turn it on the network. If the tape does not move smoothly, then the machine must be fixed, observing safety precautions, turn on and manipulate the guide roller to center the tape. More precisely, the work surface can be centered directly in the course of the work. Some models are equipped with automatic tracking and do not require manual centering, although they are more expensive.

Efficiency The use of the tool depends on how fully it is used. With the help of a grinding machine, you can not only work wood surfaces, but also sharpen incisors, axes, knives, shovels, chisels, and other tools. Before working with a metal surface, it is necessary to thoroughly clean the device from dust, since in the process of operation the metal may spark.

It is necessary to process plywood and all surfaces trimmed with this material extremely carefully, at minimum speed.

Sometimes people ask the question - "Which car is better to buy - tape or eccentric?" These are complementary grinders. For primary processing tape is used, and for the finishing grinding - eccentric. If there is not much work to do, it is worth choosing an eccentric one, they are more versatile.

Photo: boschmarket.com.ua

If there is such an opportunity, it is better to use a vacuum cleaner instead of a dust collector, which does not cancel glasses and a respirator. And for fixing the instrument in a convenient position, it is more expedient to use a special stand that can be selected for any type of machine individually.

Care and cleaning of tape machines includes cleaning the tape with a special strap. Usually, if you use a tool for processing succulent tree species, the tape quickly clogs. To clean the abrasive, you need to fix the device working surface up, and then hold the strap along the tape against its movement.

- If the waste dust is collected in the bag, it must be cleaned after each use of the tool.

- Any equipment you work with requires some care. Keep equipment clean!

Safety

Despite the fact that sanding machines belong to safe equipment, compliance with some rules does not hurt. In any grinding operations, it is necessary to protect the organs of vision and respiration.

- To work with the grinder, you must use headphones, since the noise level that the device emits can harm your health;

- To protect the respiratory organs and eyes, you must use special masks or respirators and goggles that are not recommended to be removed until you remove the dust collector from dust;

- Before changing the sanding belt or cleaning the dust collector, it is necessary to disconnect the device from the mains;

- Before working with metal, it is necessary to free the room from flammable objects, materials and substances, since the treated metal can spark;

- When you turn on the equipment in the network, you must make sure that the power button is in the off position. On all machines, the power button can be locked in the on position.

Be sure to follow safety precautions, as this will save your health and minimize the risk of accidents.