In our country, the cold does not occur - they attack! Quickly and mercilessly. And the house gets cold and in the apartment, even if the heating system is working to its fullest. Or, in order to heat the house as we need, we have to force all of our stoves, boilers, radiators and “warm floor” systems to absorb a huge amount of energy, which, by the way, is very uneconomic in our budget. It is necessary to warm the house or apartment - this will allow not to freeze, and save. Let's learn to choose modern heaters.

The preface is a preface, only among modern insulating materials is not particularly dispersed with a choice. Mineral-cotton among them - the most interesting in any respect, both in practical application and in the ability to retain heat. Yes, and in terms of cost, environmental friendliness, and so on, which is already there ... So let's take a closer look at them - how to choose the right thing and what to do with them correctly.

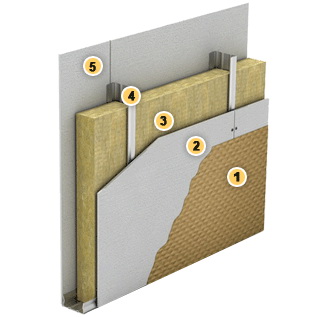

For external or internal warming - in fact, the process practically resembles a single scheme; inside the frame, comfortable stone wool slabs can be the most optimal choice. They are non-combustible and vapor permeable, and have a rather low water absorption, but sufficient resistance to deformation. All this can serve as a good guarantee that such a heater will cope with the task for many years of operation.

More detail about the performance characteristics, namely - insulation for the house should be:

- Low density, 30-70 kg per cubic meter - that's enough. Otherwise, a denser material will make it harder for vapor to escape. The thickness of the insulating material is usually not more than 15-20 centimeters.

- Elastic enough to fit snugly to the frame, rafters or other guides. Foam blowing out the gap between the frame and insulation can not be!

- Hydrophobic, so that after the next wet (or the only, accidental) to dry out easily and easily restore all its technical properties.

- When choosing several materials - fairly uniform, capable of combining. It is possible in principle to combine thermal insulation, but it is imperative to ensure that the less dense material is higher during installation than its more dense counterpart.

- In this case, dense insulation like penofol can be used, but only such materials should be laid not between the frame guides, but above or below the solid plane. In the plates of such materials, the presence of grooves is obligatory, and with thin insulators, the gaps between the blades are not allowed.

Photo: tsstrade.ru

As for penofol, it can be used in combination with mineral wool insulators, but not independently - if, of course, you want the technology to be observed, and in your house it is really warm. And put it correctly, because any gap is a potential bridge of cold, and for steam - a free passage. Penofol is laid overlapped, and if a bridge is still obtained (under difficult conditions), then such places are glued with construction tape or adhesive tape.

So the essence of the choice of materials is not in determining the name or manufacturer, but in identifying and selecting its properties depending on the specific circumstances. And also in the layout of materials.

What we have around?

Insulating materials are designed to separate two spaces: a comfortable zone for a person and the surrounding environment. And these two zones, most often, have completely different temperature indices (at the same time, drops can sometimes reach up to 50 degrees!). And different pressure, and different humidity too. This can lead to damage to the mineral wool or to the loss of its basic characteristics.In order to preserve the properties of mineral wool for the entire declared operational period, it is necessary to observe certain technological rules when installing it.

Vapor barrier. Indoors humidity is almost always increased. If moisture vapor penetrates freely into the insulators, then it also begins to “soar” in it, moving, rushing to the outside. Then, late or not late, the temperature of these vapors will reach the point at which the steam simply condenses. That is, moisture will appear in the layer of mineral wool insulation, small droplets. A wet, damp mineral wool will no longer be a heater.

Here you have another problem of choice: either choose stone wool, which is a separate material for wall insulation and can not get wet, or go the other way, complicating technology. How to complicate? To block the road for moisture vapor - for this purpose, a vapor barrier film or a special membrane also closely adheres to heat insulators. The vapor barrier is located on the warm side of the plate, that is, on its inner surface. Less throughput of such a film means less cotton will get wet. The technology of laying and fixing vapor barrier films and membranes is a separate topic, it does not affect the choice of materials.

In general, it turns out a kind of layer cake or a sandwich - as someone tastes better.

Diffusion films. In any case, at least a small amount of vapor, but in the insulation will fall, one way or another. But if they got there, should they somehow leave the material? And we want it to take as little time as possible. In our heat insulators with their low density (and we wanted to choose such ones, remember?), The moisture pretty soon gets to the outside. So let it fall, for this we chose such material! Only here the moisture should not linger, it must go out without encountering obstacles and obstacles. The most ideal option is to leave the insulation in general aired from the outside, that is, open. But it cannot be so, it must be closed, otherwise from facing materials such as siding, and any other, insulation will get moisture from condensate or small leaks. Therefore, the top insulation should also be protected by a film. Which (film) should not let droplets of moisture inside, but at the same time, freely give a way out for couples. In short, the coating of our insulation material should have a sufficiently high vapor permeability. These films are called diffusion.

Photo: tsmos.ru

New mineral wool insulation initially on the production from the outside is covered with similar films. Or they are not covered, correctly you noticed, when you monitored the market for insulating mineral wool. And those that are covered do not always meet our standards. Or our requirements. Or our planned materials costs. And now again there is a choice: either to acquire and build the technology of insulation with a material already equipped with a diffusion film, or to complicate the installation technology, independently mounting such a film on the surface. And in fact, and in another case, there are pros and cons.