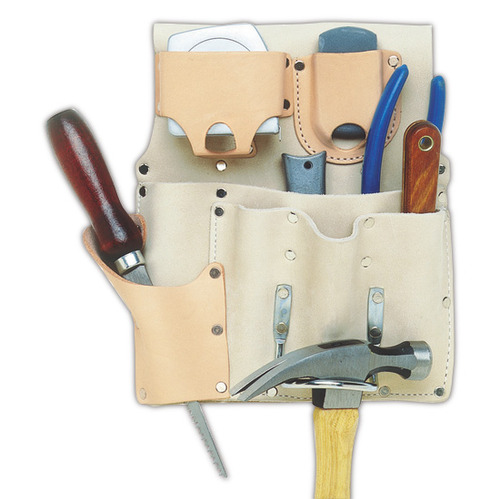

Photo: www.kunysleather.com

The peculiarity of working with drywall is that despite the seeming simplicity of the whole process, its installation will require a sufficiently large number of tools and accessories. You can do without some, without the others. Much depends on what and how much is planned to do.

If plasterboard works are performed as part of repairing your own apartment, you can go “hard and long” along the way, but at the same time save on the purchase of a significant part of the tools. Although in this case, much depends on what exactly is planned to be done: it is quite possible to simply align the walls and ceiling with a minimum set, and if a multi-level ceiling with lighting is conceived, you will need almost everything.

How to cut drywall?

Drywall sheets require high-quality, accurate and accurate cutting. In order to achieve the desired result with minimal effort and without wasting your nerves, you should pay attention to high-quality tools that are specifically designed to work with GCR.

Inexpensive wallpaper knife may be suitable only for those cases when it is necessary to perform elementary work of a small volume (for example, to sew up a plumbing riser). Blades, originally designed to work with paper, are long and thin, so when cutting GCR will often bend and break.

Photo: sila-sveta.by

When cutting with such a knife, the end of the cut element will always be uneven and will require adjustment. The bends of such a surface will be small (2-3 mm), but this will require leveling the material with a plane, and then finishing the surface with a putty. And so with every piece of material. The maximum that can be done with their help is to cut even strips of material. But to remove the chamfer, to make a hole or a curvilinear element with its help will not work.

Special drywall knife also consists of a handle and replaceable blades, but as always the whole essence of the design is in the details. A quality blade should have a firm, well-set blade that will not bend even under high pressure.

The most convenient and practical specialists are painting knives with a segment blade of a standard width of 18 mm in a metal frame with a screw stopper and a rubberized grip. If you plan to work with GVL, GVLVO or GVLVO, which contain reinforcing particles and fibers, you should pay attention to the construction knives of a special series for working with these materials.

A knife is a necessary minimum for work, but if large volumes are planned, a special one will be very useful. cutter "plattenshneider". With it, you can easily and quickly cut even parallel strips of material with a maximum width of 630 mm. The design includes two blade discs that undercut the cardboard on both sides at once. In comparison with the same operation performed with a knife, there will not be a particular advantage in speed, but the incision will be easier and will require less effort.

Hand saw indispensable when working with GCR. Without it, in principle, it is impossible to make cutting curvilinear structural elements.

Photo: www.bal-stroi.ru

It has a small size and fine-toothed cloth that never crumbles the material.

If it is necessary to make holes for the subsequent installation of sockets, lamps or switches, it is very convenient to use set of circular cutters standard sizes.

They are used as special nozzles for electric drills with a diameter of from 60 to 95 mm. The same result, but in a wider range can be obtained using ballerina for hypocardboard.

With it you can make a hole with a diameter of 12 to 230 mm.

If it is necessary to use curved surfaces as part of a structure (for example, in the construction of an arch), in some cases transverse incisions are used on one side of the drywall to bend it later. But there is a special tool that allows you to perform this operation very quickly, efficiently and without the risk of breaking the sheet. There is a special needle roller to work with drywallwhich, when rolled on one side of the material, leaves behind a perforation.

Photo: fortune-tools.com

After that, the surface is moistened with a brush, water penetrates into the gypsum core of the sheet, and it becomes flexible. This makes it easy to bend it to the desired state by the perforated side inwards.

Plasterboard Power Tools

Drywall Screwdriver

The main tool of any drywall has always been and will be screwdriver. In extreme cases, with a small amount of work, you can use an electric drill or electric screwdriver, but the work will take several times longer. It cannot be said that any tool will do (although if you already have it, of course, you should not buy it specifically for repair).

Photo: stocktools.ru

If you decide to buy, you should know how to choose a screwdriverand especially it is worth paying attention to the following points:

- the device can be powered from a network or battery (in the first case, the tool will last longer and will not require periodic charging, but working with it will not be as convenient as with its wireless counterpart);

- When using a network tool, it is important that the cable be long enough;

- ergonomics and comfortable weight are important (the screwdriver will be needed constantly and for a long time, so it is important that the hand does not get tired, it is easy and comfortable to work);

- small dimensions, so that you can mount the profile including close to the wall;

- the presence of a lap mount (this is especially important when working with headlining);

- the tool must be equipped with a removable stopper in order not to worry that the screw will break the gypsum when tightening the screw;

- 300-500 revolutions per minute is enough to work with gypsum plasterboard, so buying a powerful unit is not necessary in this case.

Especially for professionals who are constantly engaged in plasterboard work, in which thousands of screws and self-tapping screws have to be tightened at each object, manufacturers offer cluster (or tape) screwdrivers .

By their principle of operation, they very much resemble an automaton: they also have a tape with fasteners, which automatically in the process of work moves, feeding them to work. The average working speed is 4-5 screws per second. The advantages in speed are obvious, but on the other hand consumables will cost about twice as much as usual. The price for a Makita 6821 cassette screwdriver is about 12,000 rubles, the SENCO DuraSpin DS200-AC (USA) is about 10,000 rubles, and the Bosch GSR 6-45 will also cost 11-12,000 rubles.

Perforator

The peculiarity of the choice of a suitable perforator for mounting a drywall is that it must necessarily be able to work in the mode of drilling, hammering and a jackhammer.

In principle, for work with concrete or brick walls there will be enough power of about 500-550 watts. It is important that it is not heavy, reliable, well protected from dust and convenient to use.

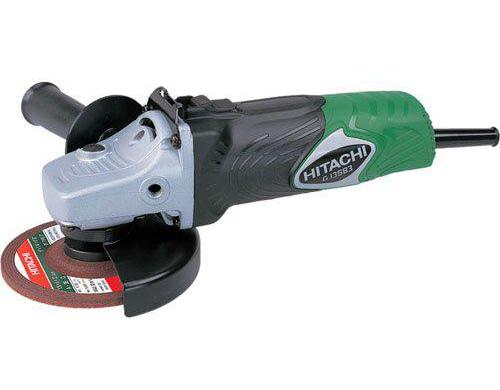

Bulgarian

Angle grinder (Bulgarian) is used to cut a profile made of thick steel (0.55-0.6 mm).

Photo: kokosy.com.ua

Most often, this is an original high-quality profile, which can in principle be cut off with metal shears, but in this case, the cut is often uneven, with burrs, and requires additional processing.

Hand tools for drywall works

Scissors for metal for cutting profile. It is best to have them in duplicate (one with long lips and the other with short ones).

Profile cutter for making holes, it is very easy to operate, reminding a punch by its principle of operation. Through such holes in the frame you can easily lay any cables, electrical wiring inside the plasterboard construction.

Photo: xl-stroy.ru

Before buying a cutter to work with drywall, it is important to know that it only works with a metal profile up to 1 mm thick. A feature of this instrument can be called its sensitivity to work in dust, especially when it falls into the hinge area.

Peeling plane (rasp) for drywall. This tool is used for machining end surfaces, allows you to remove excess material on the edge after cutting.

Photo: www.bal-stroi.ru

Structurally, it is a metal case with a handle, on which a blade with a multitude of cutting edges is mounted, which is fastened with a tension screw.

Edging Planer used for chamfering with the transverse edges of the material. This is necessary in order to increase the area of the seam between the sheets for a more accurate finishing of his putty.

For these purposes, you can use a painting knife, but the speed of work will, of course, be very low.

Mounting gun used only professionals, who with its help can very quickly fix the frame in hard concrete, steel, wood, brick.

Photo: www.tsstrade.ru

Safety in the operation of the instrument is guaranteed by an electronic control system, the presence of protection against a deliberate shot, the resistance of all elements to high temperatures.

Measuring instruments

The result of all the work depends on how accurately and correctly the surface markings and measurements of the material depend on, so a high-quality and efficient measuring tool is needed. Today there are a lot of handy instruments offered that allow you to complete one of the most crucial and long stages of work quickly and easily.

Roulette - the necessary minimum, allowing to measure the necessary distances when performing a marking. Its obvious shortcomings can be called the fact that it tends to fold and bend.

Photo: shopv.ru

If you choose such a tool for yourself, it is better to give preference to a tape measure with a sufficient length and width of the tape, as well as a magnet on the zero mark.

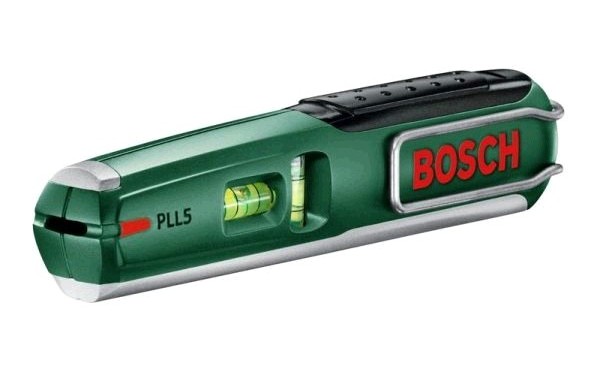

Level necessary to determine deviations from the vertical and horizontal, transfer the angle of inclination of one of the structural elements to another. In working with metal profiles it is very convenient to use a bubble level with a magnetic stripe.

To align the ceiling is convenient to use hydro level. The simplest water level is a hose filled with water and works on the principle of communicating vessels. Its advantages are quite high measurement accuracy, low cost. The disadvantage is to work alone with the hydro level is difficult, you need a partner.

Photo: www.stroydvor-t.ru

Professionals often use a laser construction level, which allows them to quickly perform markings within 100 m (although the maximum accuracy is ensured only at a distance of less than 10 m, which in most cases is more than enough).

Photo: images.shopv.ru

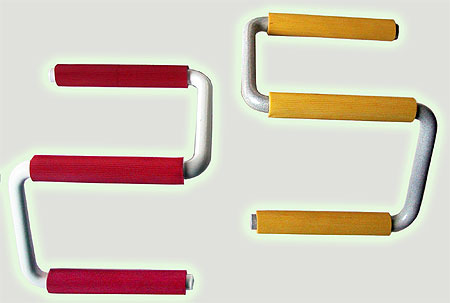

Drywall Lifts

Such devices are designed to make the work as convenient and fast as possible. Some of them are really difficult to manage, especially if there is only one person working. As an example, capture, allows you to transfer a sheet of drywall to one person.

Photo: www.specialinstrument.ru

If two people work, you can use special carrying handles: under their own weight, the sheets are held between the supports.

Worth mentioning separately mounting support, which will keep the sheet of gypsum board in a vertical position during its attachment to the frame. This device allows you to work normally independently, without attracting assistants. It is possible to adjust the device in height in the range of 5-50 mm.

Among all the above-mentioned tools for working with drywall, there are those without which it will not be possible to perform a high-quality installation, the rest can significantly speed up the work, make it more convenient, more comfortable. It all depends on the individual approach to work and the task, the choice is yours!

And finally - a very interesting video about how professionals work with drywall, what tools they use and how they organize their work.

Recommended for viewing!