Energy efficiency today is supported in all directions and at all levels, including many government programs. One of the areas of energy conservation is the development of new heating equipment. Manufacturers one after another try to introduce new technologies. But is there any real benefit to the ordinary person from such an all-time haste? Who, for example, decided to put a condensing boiler in his house ...

We will try to tell a little more detail, and a little from a different point of view. And let's start with whether condensate is useful or harmful for the heating process.

.jpg)

Condensation problems

This is generally accepted opinion - the condensate that is released in boilers only hinders the process, causing many problems. What are they and what scares?

During operation of any boiler, the moisture produced must be withdrawn and disposed of. Especially a large amount of condensate is released at the very time when the equipment should work smoothly and incessantly, that is, in the frosty season at negative temperatures. During periodic stops of the boiler, the chimney starts to cool down, the process takes place from top to bottom, moisture is formed on its internal walls and flows unsuccessfully to the boiler. Many manufacturers quite often just forget about it, limited to a simple trap.

The diverter does not neutralize this moisture, but simply dumps it into the sewage system - and this is not allowed!

At the same time, those manufacturers who “forget” intentionally can also argue to the inhabitant that, according to the technological conditions, with the heat output of condensate boilers up to 200 kW, moisture can be discharged into the sewage system without neutralization. Do they all of us incomprehensible and untested technical conditions will be read out so that the equipment is not brought to mind? Then why the leading foreign eminent manufacturers of the same equipment include special systems for the neutralization of condensate in the mandatory set of heating equipment? For example, the well-known firm Grundfos completes boilers with special pumps.

Why do we raise such problematic issues specifically for the average user, who does not need to understand the subtleties? For a practical presentation of the problem. To make it more visual, try to explain on the fingers - how to calculate how much condensate is emitted by the boiler.

First of all, of course, it depends on the power of the equipment. But in almost any case, in order to burn one cubic meter of gas, you need about 9 cubic meters of ordinary air, which forms approximately 2 cubic meters of water vapor. Then 1.5 - 1.6 liters of condensate will settle out of these vapors. It turns out that your condensing boiler, for example, De Dietrich Innovence MC 45, to the maximum can form eight liters of moisture per hour! And you ask why the pump.

Chimney problems

We change the boiler, which is already there, to the condensation one, and we leave the old chimney, then we have to bother and waste time and money. And completely wrong, because for kondenskotl need another, a special chimney of acid-resistant materials. Well, it is possible to interpret such a need and the fact that lead or something similar should be used in the materials is the same, also frightening, but in fact everything is a bit simpler. Or much ...

Photo: gazplus.ru

In fact, it is necessary to use only ceramic or plastic chimneys. Iron - it is impossible, but it seems they don’t do lead.By design, chimneys for condensing boilers are almost the same as those developed and presented on the entire world market for simple gas boilers with a closed combustion chamber. After all, all the same, the products of combustion will be ejected by force, so that there could be no major changes.

Here! Forced smoke removal provides great opportunities for additional connection to coaxial chimneys with two-pipe systems. And the boiler can be connected to the air intake system from the room. Who is doing this? There is a standard steel chimney - here you have a condensing boiler! Or how is it still fashionable to say - tin! That is, in tin, from which chimneys can be run.

Types of equipment - just in case

Today in the market of heating equipment there are both gas and liquid-fuel household boilers, which may have a condensing design. They are executed both in wall and in floor variants. Wall not so powerful, they have an average of 20 kW, and the floor - this is more serious units, which are characterized by a capacity of 30 kW or more.

With all this, the boilers can be either single-circuit or dual-circuit, and be designed either for heating only, or for heating and hot water. The problem of choosing among all types and types is relevant today, as it is the wrong selection of equipment not only increases its cost, but also reduces efficiency.

All about boiler efficiency

Is it possible to get a condensing boiler efficiency of 110%?

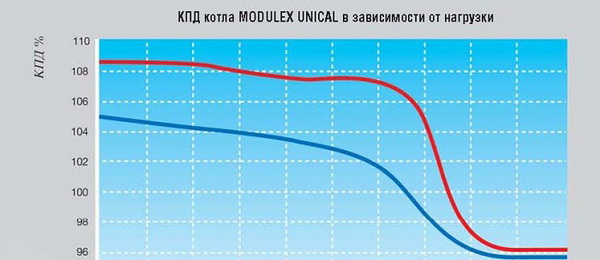

Physics has told us all its life that the coefficient of efficiency simply cannot, by definition, exceed one hundred percent. Even a hundred - can not be, because there is inevitable heat loss, and any other loss of energy. And the manufacturers unanimously declare to us the efficiency of as much as 104 - 110%! How can this be? We must deal with this matter, what is the catch here.

The new energy-efficient equipment produces not one, but two types of heat: the lowest and the highest. The first is that which is formed in any boiler in which the fuel is burned. A higher form is formed exclusively in the condensate chambers, this heat is composed of the sum of the heat from the combustion of fuel and the heat obtained from the condensate. Calculations for comparison are, of course, carried out on the lower heat. And if the manufacturer indicates 108% efficiency of its product, then this simply means that the boiler uses all the lowest heat of combustion, that is, 100%, plus an additional 8% of the heat of condensate, of the highest heat. They lie, in one word, but neatly.

So we can say that the real efficiency of the condensing boiler is still less than one hundred percent, only such equipment can use the additional energy of the heat of water vapor. And in fact, the efficiency will be no more than 97%, but this is quite a lot.

In what mode to drive the boilers?

Horse breeders do not constantly give their full potential. In order for the heat loss along with the smoke and gases to be as low as possible, constant condensation of water must necessarily occur in the heat exchanger. This becomes possible if in the heat exchanger at least a part of the entire surface has a dew point temperature, and preferably slightly lower. If we consider natural gas under typical conditions, then the dew point is about 57 degrees. And if you want the boiler to work "in full", in return flow temperature should not rise above 57 degrees. If this condition is not fulfilled, the equipment efficiency will be reduced by the same 4-10 percent. Of course, the efficiency of the condensing boiler will still exceed the performance of a conventional boiler by a few percent - this is due to the fact that the total area of the heat exchanger is larger.

As a result, it is clear that the efficiency of the condensing unit will then be higher when there is a low temperature mode in the heating system.But then the heating system should be provided with appropriate, and not include new energy-efficient equipment in the existing one.

Such a system should be pre-designed specifically for the condensate hotel.

During the design of the engineering network, it is necessary to determine the temperature of the return not more than 60 degrees even during extreme cold periods. Then, if there is only a small frost outside, the return line will supply coolant with a temperature not higher than 45-50, and the equipment will work in the most optimal mode.

The most effective combination of a heating system with condensing boilers is when there are additional heat sources in the apartment or house, for example, the “warm floor” system.

In conclusion, in any case, if you want to change not the entire energy consumption system in your house, but only the heating system, you need to plan everything in the complex. Otherwise, energy efficiency will be non-energy efficient!