A perforator, like any power tool, may occasionally crash and malfunction. Today I will tell you which ones are the most frequent and how to prevent them in time.

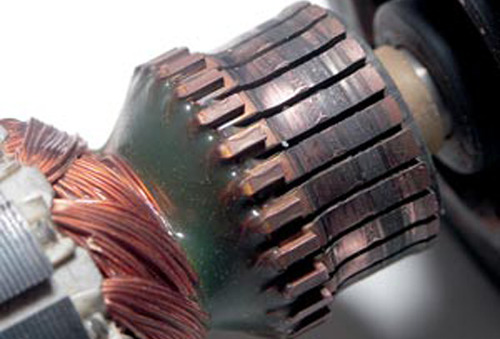

The whole design of the punch can be divided into electrical and mechanical parts. Of the most characteristic breakdowns of electricians that can be fixed in the field myself, I note the malfunction of the start button and the wear of the brushes. Problems with the engine (“lumbago” of the winding, mechanical or electro armature failure, etc.) should be solved by a professional electrician-wrapper.

Photo: instrumenti-vse.ru

Button and graphite brushes can even go in the complement to the new tool. Find them on the market, or order online, work will not be. It is only important to remember, and even better to photograph the position of the contacts of the factory connection, and to pay attention to the configuration and the clip in place of the brushes. The case can be disassembled by any master, even far from solving electrical problems. The breakdown can be recognized in time due to excessive sparking punched into the hull, noise and the characteristic smell of burning from the hull. Do not bring the tool to the final combustion, as this can lead to serious engine damage. It is most practical to buy these inexpensive consumable parts in advance and replace them on time.

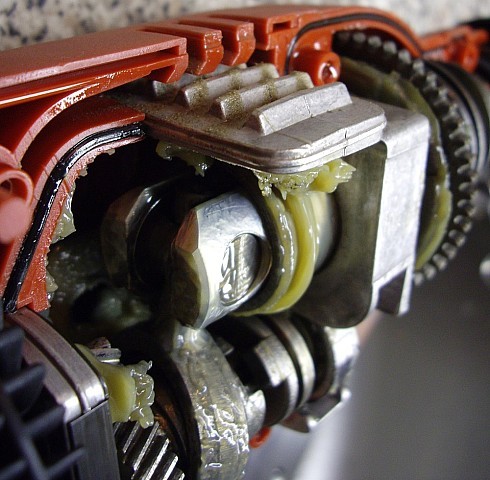

Photo: asio.ru

Mechanical components become unusable as a result of excessive dust, dirt and solid particles in the moving part, or due to exceeding the permissible loads on the chassis in work. Their replacement, except, perhaps, the finished cartridge is somewhat more difficult. Reserve them, too, is unlikely to save enough. The best way to avoid sudden breakdowns will be a routine inspection at a repair shop. They will pick up and lubrication, and bearings, and shock components. Alternatively, you can keep a backup tool ready.

Timely detected and prevented damage will keep the punch working and will not allow the order to stop at the wrong time. Masters should remember that a tool breaks not when it is idle at home, but at the height of work, and you need to be prepared for these troubles and prevent them in time.