The current situation with home 3D printing devices in many ways resembles the situation that prevailed around the semi-submerged semi-axes — the same communities of enthusiasts, the ability to “finish” the printer for themselves and other DIY attributes. The devices working right out of the box are available, but their possibilities suit only the most undemanding users, and even then only at first.

A 3D printer is a device designed to physically translate a prepared digital three-dimensional model into a specific material. The technology is going through a stage of active search and improvement, therefore a variety of implementation options can lead an untrained person to a dead end. This article is designed to provide first aid in such a difficult choice among custom-made 3D printers.

The main criteria for choosing a 3D printer

Choosing a 3D printer, first you need to decide which technology three-dimensional print best suited to achieve your goals. Currently, about two dozen approved developments of various companies are known, but FDM and laser stereolithography (SLA) are most widely used in compact devices. The essence of the first technology lies in the heating of a special plastic thread to the melting temperature and the layer-by-layer formation of an object from a melt microdroplets in accordance with its digital model. The advantage of the method is the relative cheapness, and the disadvantages are the need to use temporary supports when creating overhanging structures and a large surface roughness.

When stereolithography prints are formed as a result of solidification of the liquid photopolymer resin under the influence of hard ultraviolet radiation. Although the construction of a solid copy of a three-dimensional model is also carried out in layers, this technology provides higher printing accuracy than FDM. The main disadvantage is the high cost of consumables and the higher cost of the installation itself.

The second criterion when choosing a 3D printer are characteristics of the substance used to create prints. If the printed model is supposed to be actively exploited, it makes sense to use an ABS thermoplastic or high-impact polystyrene HIPS. For prototypes and short-lived layouts, the PLA polylactide capabilities will suffice. Decorative art crafts are best formed from composite materials, and Ninja Flex is suitable for making elastic copies.

It should be borne in mind that some manufacturers of three-dimensional printing technology impose special restrictions that allow the use of only original consumables. Consumables for photopolymer printing almost all are developed for specific installations and it is extremely difficult to choose a compatible resin with alternative properties.

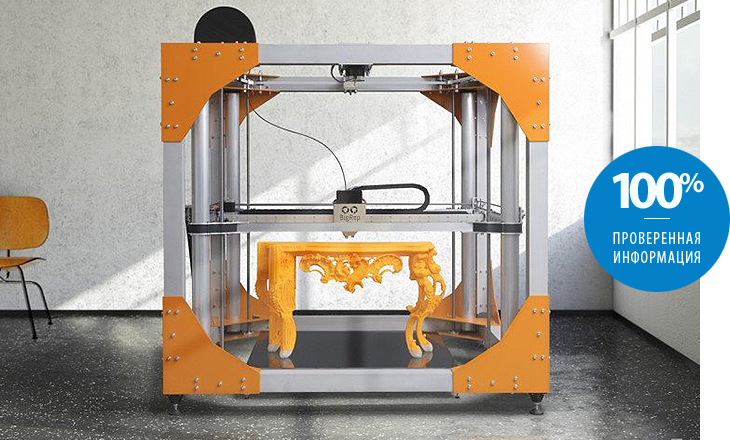

Sizes of a working zone establish the maximum dimensions for the object being formed. If for prototypes or layouts the presence of components is not a critical indicator, then for functioning models of large size the integrity of the structure can be extremely important.

Photo: hostingkartinok.com

Other factors affecting the choice

- Number of extruders determines the number of simultaneously used materials (colors), as well as the possibility of forming temporary supports from the soluble substance.

- The higher resolution 3D printer, the more accurate the model can be printed.

- Open license on software and hardware allows you to use third-party software and easily modify the system.

- Hardware implementation a particular site, such as the ability to automatically level the platform and calibrate angles or use a deltoid positioning system, provides more accurate and faster printing of a 3D printer.

Most Popular Manufacturers 3D printers

As in any other actively developing business, it is very difficult to determine the future trendsetters. First you need to mention the company 3D Systems - A veteran of the industry and a developer of many know-hows. Products are also very popular. MakerbotIndustries, ShareBot, Ultimaker, Zhejiang Flashforge 3D Technology Co (FF3DP), Beijing Tiertime Technology Co (PP3DP) and many other similar companies.

In the new business just miss

Choose a 3D printing device that takes into account the use of future prints. Otherwise, you run the risk of producing a working model that is soluble in water, and a model made using photopolymerization technology may delight the customer with the smoothness of the lines, but it hurts you enough.

When choosing a 3D printer, avoid devices with proprietary solutions. They will not allow the use of non-original components to upgrade the system and are poorly compatible with popular software for the preparation of models.

Focus on the installation of a heated platform. Even if you do not intend to deal with ABS plastic now, you may need it later.