14 best welding inverters

Buy a good welding inverter so that you can use at work, at home and in the country, where 220V is not always the case - a difficult task. We will try to help with this.

Thanks to the development of inverter technology, welding machines have become compact, economical and easy to use, even for beginners. Thanks to this, you can meet the device for manual arc welding or semi-automatic in many garages and private workshops. Stable and high demand for welding inverters makes competing manufacturers constantly improve their model range, reduce prices and develop corporate service.

Selection criteria

It is rather difficult to choose the best welding inverter - the variety on the market is breathtaking. But experienced welders do not try to experiment, turning to products already familiar manufacturers. Choose only proven brands and their own work. After all, if a manufacturer is serious, he always keeps the quality at a high level - both in semi-professional and professional devices.

Therefore, before buying a new inverter, look at the products of those manufacturers, which was already in operation. Even if they did not work themselves, then colleagues would advise. Based on many years of experience, a list of leaders of manufacturers of welding inverters has been formed, which we bring to your attention by taking “for work and home” devices for comparison. That is, with which you can earn, and cope with household chores.

Depending on the mode of operation, the inverters fall into three categories:

- manual arc welding machines (MMA);

- semi-automatic (MIG / MAG);

- argon welding machines (TIG).

Since several devices in our rating are multifunctional, the comparison was made not only in terms of the main function, but also in the category “Best Universal Apparatus”.

| Category | A place | Name | Rating | Price |

|---|---|---|---|---|

| The best inverters for manual arc welding | 1 | FUBAG IR 200 | 9.5 / 10 | 8 010 |

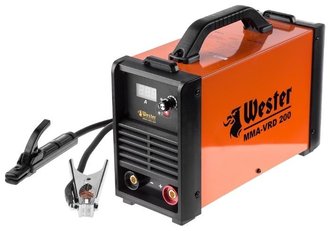

| 2 | Wester MMA-VRD 200 | 9.4 / 10 | 10 200 | |

| 3 | ELITECH AIS 200 | 9.0 / 10 | 27 100 | |

| 4 | Resanta SAI-220 | 8.9 / 10 | 7 920 | |

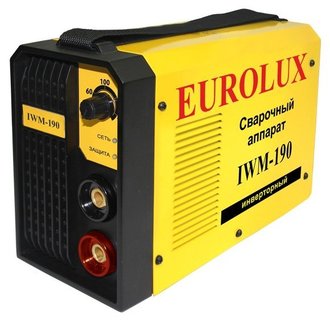

| 5 | Eurolux IWM-190 | 8.7 / 10 | 4 410 | |

| The best welding inverter semi-automatic | 1 | BLUEWELD Starmig 210 Dual Synergic | 9.6 / 10 | 61 390 |

| 2 | Aurora OVERMAN 180 | 9.5 / 10 | 26 000 | |

| The best universal welding inverters | 1 | Aurora INTER TIG 200 AC / DC Pulse | 9.8 / 10 | 40 300 |

| 2 | Torus 200s Super | 9.7 / 10 | 17 350 | |

| 3 | Svarog TECH ARC 205 B (Z203) | 9.6 / 10 | 19 940 | |

| 4 | Quattro Elementi MultiPro 2100 | 9.5 / 10 | 19 090 | |

| 5 | Fast and Furious-161 | 9.5 / 10 | 11 150 | |

| 6 | Cedar MIG-160GDM | 9.4 / 10 | 31 500 | |

| 7 | BLUEWELD Prestige 186 PRO | 9.0 / 10 | 16 470 |

The best inverters for manual arc welding

|

8 010

This welding inverter boasts not only a high maximum current of 200 amperes, which allows it to be used for welding and cutting metal with all types of electrodes with a diameter up to 5 millimeters, but also with a wide range of operating voltages. The efficiency of the welding machine is maintained when the voltage drops in the socket up to 150 V, which will be appreciated by garage owners and residents of rural areas. To facilitate the work, anti-sticking, afterburner arc and hot start functions are provided, thanks to which even a novice can work effectively with the IR 200.

The overall score is reduced only for a low PV (40%). Simply put, when operating at maximum current, every 4 minutes of operation must have at least 6 minutes of cooling. Main advantages:

Minuses:

|

9.5 / 10

Rating

Reviews

Reliable and unpretentious device from a reputable manufacturer. They can even cook a novice welder, so the price can not be called high.The board, unlike cheap Chinese welders, is coated with varnish - the inverter is not afraid of moisture and dust. |

|

10 200

This compact welding inverter is very attractive in its characteristics: with a maximum welding current of 200 A, continuous operation is already possible at 126 A, that is, in most cases it will not require interruptions for cooling: you don’t cook permanently massive structures with 5 mm electrodes? All the functions that "supposed" to have a modern inverter for MMA welding, are also present here - "anti-sticking", and "hot start", and arc boost. Since the no-load voltage here is 65 V, for safety at high humidity, the manufacturer introduced a VRD circuit into the circuit, which automatically reduces the voltage at the terminals when welding is not conducted, but the device is not turned off. In general, a good inexpensive welding inverter for home, garden, garage, deserving many positive reviews on the forums. Especially the inverter will be of interest to those who often have to work from the ladder when the welder hangs on his shoulder: with “Wester” it is quite convenient. The only thing that would not hinder him is to increase the current regulator, it is not very convenient to twist it in the corners. Main advantages:

Minuses:

|

9.4 / 10

Rating

|

|

27 100

Although the marking of this welding inverter pushes to the idea that the maximum welding current here is 200 amperes, in reality the reality is a bit more modest: it can only get 180 A out of itself, and only 40% at PV. Thus, the optimal choice for him is welding with electrodes of 2-3 mm, with the Quartet, planned smoke breaks will be required if you do not strive to check in practice the safety factor of the welder. As for the margin of safety, here this term can be understood almost literally: compared to many members of its class, Elitech will seem a real “brick”, because it weighs 8 kg - one and a half times more than many inverters with the same maximum current. His circuit completely satisfies modern ideas about welding inverter: arc boost is provided, current consumption is quite acceptable. So, it can be safely used in the garage arrays, where the wiring was still divorced "under Tsar Peas" without counting on serious loads, to carry to the dacha. Main advantages:

Minuses:

|

9.0 / 10

Rating

Reviews

A good welding inverter for the garage, does not overheat, in weak networks it works without problems. The arc ignites easily, is carried out smoothly. |

|

7 920

Inverters under the brand "Resanta" have become very popular due to decent quality at an affordable price. The model ranked in third place with the highest maximum current: 220 A. This allows the owner to work with electrodes up to 5 mm in diameter, boil massive metal structures and cut metal with an arc.

The device not only provides a large welding current, but can also work on it for a long time: its PV coefficient is 70%. The design provides the functions of "hot start" and "anti-sticking", but there is no arc boost (increase in current at the time of ignition). Therefore, for the novice welder SAI-220 is less convenient than the leaders of the rating. It is worth noting a wide range of operating voltages: 140-260 V. Unfortunately, the overall score, despite the excellent technical characteristics, has to be reduced due to frequent complaints about breakdowns of Resant inverters. The device requires more careful storage (the board is not covered with varnish) and circulation. Main advantages:

Minuses:

|

8.9 / 10

Rating

Reviews

The device is cheap and powerful, but rather gentle: the fan breaks easily when foreign objects hit, the board is not covered with a protective coating. Therefore, it is better not to work near the grinder, if you do not want to remember the address of the repair shop. I did not come across a repair (pah-pah), but I heard complaints from my friends. |

|

4 410

Despite the external frivolity (the feeling that Russian-language markings are stuck in a hurry), Eurolux IWM-190 may be of interest to many people who do not need hard work with a welding machine, and most of the time collecting dust in the garage: in this case, it is logical to get a good inexpensive primary class inverter. By itself, the inverter is compact, although I would like complete cables and more authentic those meter "stubs" that the manufacturer offers. With a stated maximum current of 190 amps and a PV of 70% for a standard “garage-household” electrode, 3 mm characteristics are enough with a margin, and if necessary, you can use a “four”. Naturally, for this money it is difficult to expect from the manufacturer the use of “anti-sticking” modes or arc afterburner in the inverter: its design is very simple, which, in principle, also has its advantages. It is hardly worthwhile in the budget segment to strive for a more complex structure, here simplicity and reliability are in priority. The scheme itself is already well known to both welders and repairmen for the numerous “Resants” sold in our country - as often happens with Asian-made vehicles. So even in the event of problems outside the warranty period, it will not be difficult to “revive” the inverter - but it is also cheaper compared to “Resants”. Main advantages:

Minuses:

|

8.7 / 10

Rating

Reviews

For the garage and the dacha, the choice is good - this current welding machine eats a little, so that in a weak network it draws three of them without problems. |

The best welding inverter semi-automatic

|

If we ignore the price, which is not exactly democratic here, then this semi-automatic is very interesting. Already, outwardly, he stands out from among his own kind with a large LCD screen, which is very, very informative. However, the main thing here is not appearance, but “stuffing”: the proprietary term “synergetic management” means fully programmatically setting the characteristics of the welding machine, selected for a specific function. Even the welding current apparatus is able to calculate itself, based on the thickness of the parts to be welded and the type of wire. If you are so brutal welder that all these “whistles” are not needed at all, then the synergistic mode can be turned off completely and the adjustments can be turned in the old fashioned way. So the impressions of this semi-automatic, of course, controversial. On the one hand, for a novice welder, it will become a real discovery, allowing you to master various methods of semi-automatic welding with maximum ease. But, on the other hand, not every self-taught welder can afford to fork out for a considerable amount, which is enough for two quite good welders. Main advantages:

Minuses:

|

9.6 / 10

Rating

Reviews

Comfortable and modern welding machine with excellent quality seams. The price, however, will make you think about buying it three times ... |

|

26 000

Welding semi-automatic "Aurora" are widely distributed in Russia. They are distinguished not only by an affordable price, but also by the flexibility of the characteristics combined with high reliability. Model Overman 180 is most popular in the amateur lineup Aurora. The maximum current developed by this inverter is 175 A, which is more than enough when working with wire with a diameter of up to 1 mm. At the same time, the semi-automatic is very economical - its power is only 4.7 kW. Unlike most models of inverters for semi-automatic welding, there is a manual adjustment of the rigidity of the current-voltage characteristics (the “Inductance” handle). Due to this, it is possible to make the work more convenient both for thin metal (preferably “soft” VAC), and for massive parts (on “rigid” VAC at high current, the sparks are less spread). Semiautomatic has unregulated post-gas time. After the termination of welding, carbon dioxide is fed into the sleeve for another 1 second to protect and cool the seam. To facilitate wire filling, the manufacturer has provided for an accelerated feed, which is activated by a button near the wire feeder. The only reason for lowering the mark was control of the wire feed speed: instead of the regulator, a simple toggle switch was set “quickly and slowly”, within these limits the speed of the feed roller was adjusted by the control electronics. This is more convenient for a beginner, but a professional welder will prefer to control the wire feed to the sleeve itself. Main advantages:

Minuses:

|

9.5 / 10

Rating

Reviews

The semiautomatic device justifies the price with high quality welding, you can adjust not only the voltage and arc current, but also the inductance - as a result, a strong and beautiful weld can be put even on thick metal, even on rotten Zhiguli. There are no claims for reliability during use. |

The best universal welding inverters

|

The marking of this welding machine unwittingly will attract not only professional argon workers, but also the fans of Malcolm Young's associates. And by the number of buttons, sockets and "twists" the front panel of the device looks something like a guitar amplifier. So, we have a very functional device, proudly carrying the mark on the certification of NAKS. The work is supported by stick electrodes and gas-shielded welding; the maximum current delivered by the inverter converter is 200 amperes in both modes. In Pulse mode, the welder can adjust both the frequency, and the balance, and the lower level of the ripple current, in the TIG mode, as you already understood, welding is also possible at alternating and direct current. In this case, it is possible to adjust the starting current separately from the operating current, adjust the balance in TIG AC mode, switch between push-pull and four-stroke modes, and in the latter, the crater setting is also available. In a word, it is a welding machine that is excellent in its universality and is able to work in a variety of conditions - from jewelry welding of thin-walled parts with argon to metal cutting with an electrode. Main advantages:

Minuses:

|

9.8 / 10

Rating

Reviews

A very good welding inverter, on aluminum and copper, it works perfectly, the mode can be customized just perfectly, the device seems to be cooking for you instead. |

|

17 350

The brand “Torus” is well known among professional welders - the inverters of this Moscow-based company survive the warranty period without any problems even under the toughest operation, without presenting unpleasant “surprises” even after the end of the warranty. The MMA / TIG inverter “200s Super” will allow the owner to operate at currents up to 200 A at PV 100 - and this means the possibility of full-fledged work with electrodes up to 5 mm in diameter. It is important that this inverter can be certified by NAKS (this option will be more expensive than uncertified by an average of 2 thousand), which is the best evidence of the high quality of the welds created by the device.The credit for this is in the microprocessor-based current curve formation scheme, which ensures not only its optimal shape, but also the stability of the characteristics with a strong voltage drop. The inverter will be equally convenient both to the welder with many years of experience, and to the beginner to ignite and keep the arc on it extremely simply, and in the TIG mode in the same way as when welding with a piece electrode. The minimum current is 20A, which makes it possible to use the “200s Super” inverter for argon welding of the thinnest parts. Main advantages:

Minuses:

|

9.7 / 10

Rating

Reviews

The best welding machine. He can work the entire shift, as they say, “without smoke breaks” - the cables will overheat faster than he does. |

|

19 940

This inverter in the modes MMA and TIG it allows you to use a welding current up to 200 A, while the PV reaches 80%. At currents less than 160 A, an efficient cooling system allows the inverter to be used without mandatory pauses for cooling. When working with the Tech Arc 205 B device, it should be taken into account that the power consumed by it in the MMA mode reaches 9 kW, and large drawdowns of the supply voltage are possible. However, due to the built-in digital indicator of the welding current, to a certain extent they can be compensated - on the devices, where the current is set on a scale at the regulator, the current should be adjusted to the desired value by eye. To facilitate welding, the manufacturer provides not only “anti-sticking” and “hot start” modes, but also an adjustable level of arc forcing during ignition. Welding safety provides the ability to enable the VRD mode (reduce the no-load voltage) in order to avoid electric shock when welding in conditions of high humidity. In TIG mode, the maximum power consumed by the inverter is 5 kW. Although it cannot be called a full-fledged apparatus for argon-arc welding (only current is regulated, there is no TIG AC mode for welding light alloys), Tech Arc 205 B can be successfully used for high-quality welding of carbon and stainless alloys, bronze and brass. The TIG Lift mode (touch ignition) will greatly facilitate the development of work with a refractory electrode. The main sign of the high quality of this inverter can be considered that it can be certified by NAKS, that is, to receive admission to responsible work on pipelines, in boiler houses, on high-loaded supporting structures. Main advantages:

Minuses:

|

9.6 / 10

Rating

Reviews

One of the best welding inverters for professional use. The device is powerful and provides high quality welding. It can work for a long time under heavy load, cheap inverters in such conditions quickly surrender. |

|

Practically the maximum possible universality is incorporated into this welding machine: the “Italian” is able to work both as a semiautomatic device and to cook in MMA and TIG modes. Of course, with a maximum current of 160 A and a low PV, it is not at all desired to be classified as professional, but in the personal workshop it will be enough. Taking into account the fact that the forcing of the arc, anti-sticking and “hot start” are entered into the design of the device, it is still difficult to demand something for the MMA mode if you work with electrodes with a diameter of 2-3 mm. Need to weld thin iron? Well, put a coil of wire and connect the burner. In MIG-mode, the device is able to work on a push-pull or four-stroke scheme, although this can not be attributed to so serious advantages - it would be better for the manufacturer to expand the TIG mode adjustments. To him the main complaint is, of course, work only on direct current.With the TIG AC, of course, the inverter would be the perfect all-rounder for a personal workshop. Main advantages:

Minuses:

|

9.5 / 10

Rating

Reviews

In the garage or in the country, this welding machine is a great helper, it covers all needs, except aluminum welding, but this is already different money, and you just need to be able to. |

|

11 150

The welding inverter manufactured by the Ryazan Instrument Plant, although it does not shake with the stated characteristics or ultra-modern design, will give the professional exactly what he needs - reliability and accuracy in the formation of the current-voltage characteristic of the welding current in the MMA and TIG modes. In both cases, the maximum welding current is 160A, but continuous operation is possible at a current of no more than 100A. Therefore, this inverter is most suitable for work with a rather thin metal that does not require deep penetration at high current. Among the advantages of the device, you need to include the ability to work with strong voltage sags - the efficiency stated by the manufacturer at 140V in the socket is well proven in practice. The “soft” arc is easily ignited and burns without splashing metal. The automatic control of the fan used in the inverter by a signal from the temperature sensor significantly reduces the amount of dust sucked into the case, accordingly making the need to clean the output stage radiators more rarely.

Main advantages:

Minuses:

|

9.5 / 10

Rating

Reviews

After the Chinese inverters, this one is like heaven and earth. The price difference pays off many times. |

|

31 500

The most versatile device in the review - it allows its owner to work both with welding wire in MIG / MAG mode, and with stick electrodes and an argon torch (albeit exclusively in TIG DC mode - for welding aluminum alloys it will not work). This inverter belongs to the family of welding machines with microprocessor synergistic control: it has only two controls - a touch mode selection button and a multifunction controller. Sequential pressing the mode selector allows you to select one of the options:

Most of the parameters of the arc is set automatically depending on the selected mode. This is convenient for beginners, while a professional welder will most likely select an apparatus with a large number of manual settings. In addition, full value operation at high currents is limited by the low PV value: long-term cooking with an electrode is possible only with its diameter up to 3 mm, which, given the high price of the inverter itself, has led to a noticeable reduction in the rating of the best welding machines. Main advantages:

Minuses:

|

9.4 / 10

Rating

Reviews

The device is expensive, but for the inverter, which can "all at once", it is not so much. Unfortunately, there is no possibility to boil with argon on alternating current. |

|

16 470

This "universal", designed for MMA and TIG welding, is quite simple (but cheap for this class): the basic mode of operation with stick electrodes is still in it, working under argon is not always convenient due to the minimum settings. So we have a welding machine in front of us rather for “garage skilled workers”, either only mastering argon in addition to the work with already familiar electrodes, or those who need TIG welding from time to time and without high requirements to the quality of the weld. The inverter is compact and quite light, which is again a plus for the garage - there is usually no extra space. It carries over voltage drawdown well, although this is not surprising at low power: the welder only consumes 4 kW, developing an output current of up to 160 A at a PV of 60%. The absence of any regulators other than the current regulator clearly indicates that the inverter is working, regardless of the welding mode at a constant current. For TIG it is not always good: the same aluminum alloys already require alternating current. So from the materials found in the garage practice, the inverter is likely to be used with stainless steel. The argon burner, by the way, will have to be bought: the Italians did not add it to the delivery set, which again hints at the primacy of the MMA mode. There is a separate nuance when choosing: under one marking, in fact, two models are produced: in one, the two-position switch serves exclusively for setting the operating mode (MMA / TIG). But the second switch has a three-position switch, and with it you can already have separate settings for igniting rutile and alkaline electrodes, which is very convenient. Main advantages:

Minuses:

|

9.0 / 10

Rating

Reviews

I cook either ink or stainless steel, so I do not need a heaped argon machine, and here for sane money the quality of welding is quite good. |

The above rating of the best welding inverters takes into account not only the technical characteristics and reliability of welding machines, but also their prevalence. Therefore, many models are not included in it: for example, it is difficult to recommend the Contact 200 MMA inverter, which, although it has excellent parameters (PV, 90% at 200 A, power consumption is not more than 4.5 kW) and price, is extremely rare in shopping networks and online stores.

Speaking of common models, one can rely on the experience of a large number of users with different experiences. At the same time, cheaper inverters are subjected to no less stringent testing in the hands of inexperienced welders than more expensive professional models that are constantly used.